Chinese medicine becomes

The new C-suite of the pharmaceutical industry

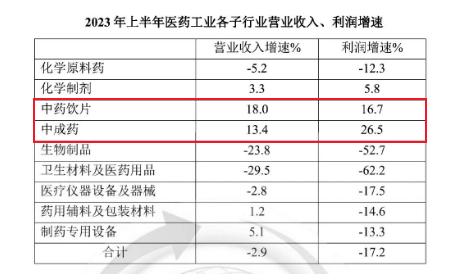

Data show that in the first half of 2023, the revenues of proprietary Chinese medicines and Chinese medicinal tablets increased by 13.4% and 18% respectively, and the profits increased by 26.5% and 16.7% respectively.

In the whole pharmaceutical industry revenue and profit are in negative growth, the growth rate of traditional Chinese medicine is double-digit: the traditional Chinese medicine industry has become the new C position of the pharmaceutical industry.

For the traditional Chinese medicine tablet industry, if you want to catch this "heavenly wealth" for a long time, the equipment industry innovation is the "top priority" that must be treated seriously.

Drying, as an important part of the processing of traditional Chinese medicine tablets, accurate and uniform control of the water content of the tablets has always been a difficult problem for the enterprises of the tablets.

Drying Dilemma

The way out is intelligence

Imprecise and uneven water content control

In addition to good raw materials and good technology, good medicinal materials also need good equipment! Traditional drying equipment is difficult to meet the demand for precise control of moisture content and uniformity in the drying process of tablets, thus resulting in loss of herbs and capacity constraints.

In the era of high-quality development of traditional Chinese medicine, how to use new technology, new equipment to empower the whole industry of traditional Chinese medicine tablets? This issue deserves deep thinking of every pharmaceutical person.

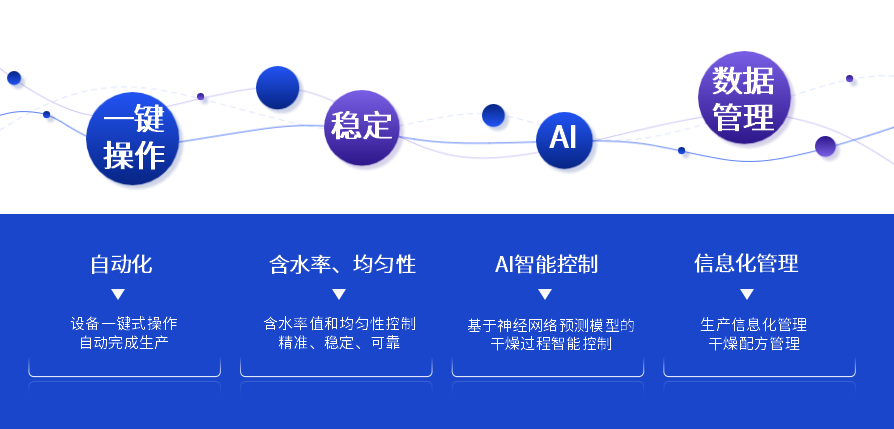

From the production side to control the quality of tablets and improve production efficiency, Lampo Technology utilizes intelligent sensing technology, AI artificial intelligence technology and industrial Internet of Things technology to point out a new intelligent way out for the dilemma of drying tablets.

The core of intelligent drying of tablets lies in the use of scientific, professional and reliable technical means to avoid uncontrollable factors in the production process and to promote the industrial transformation and upgrading process of replacing machines with human beings.

Lampu intelligent drying equipment, embedded in AI artificial intelligence model, through the neural network prediction model of the whole process of drying tablets for fine control, one-button operation, to avoid the quality deviation and loss problems brought about by manual control, and to achieve the digital management of production.

Are you, as a business leader, moved?

Drying upgrade

Energy saving and efficiency increase of more than 5 million / year

Over the years, the production of tablets has been dominated by the experience of "masters", which is the key to the cost and quality control of tablet enterprises, and the artificial error leads to uneven quality of finished products.

Lampu AI intelligent drying equipment not only perfectly solves the above pain points, but also controls the water content precision and uniformity deviation of the tablets at 0.5% - 2%, and along with the accumulation of data from the production process, it continues to learn, adjust, and evolve so that the error becomes smaller and smaller, which saves energy and increases efficiency for the enterprises of the tablets by more than 5 million yuan/year (5000 tons of drying output).

Moisture is well controlled, and the loss of herbs is less. Let the machine learning and inheritance, has become an inevitable trend of the times.

The progress of the industry can not be separated from the development of technology. 6 years of research and development experience has made LAMP Technology also plowing in the traditional Chinese medicine industry for 6 years. As a technology-based enterprise, in-depth market insight and innovative product design are LAMP's eternal pursuit.

To redefine the possibility of drying traditional Chinese medicine tablets and to revolutionize the industrial path, LAMP has been working hard.

Return list

Return list