The application of smart tobacco technology is relatively limited, focusing mainly on localized data collection and analysis and lacking overall information systems and synergistic mechanisms.

The application of smart tobacco technology is relatively limited, focusing mainly on localized data collection and analysis and lacking overall information systems and synergistic mechanisms.

Lamprecht uses digital technology to

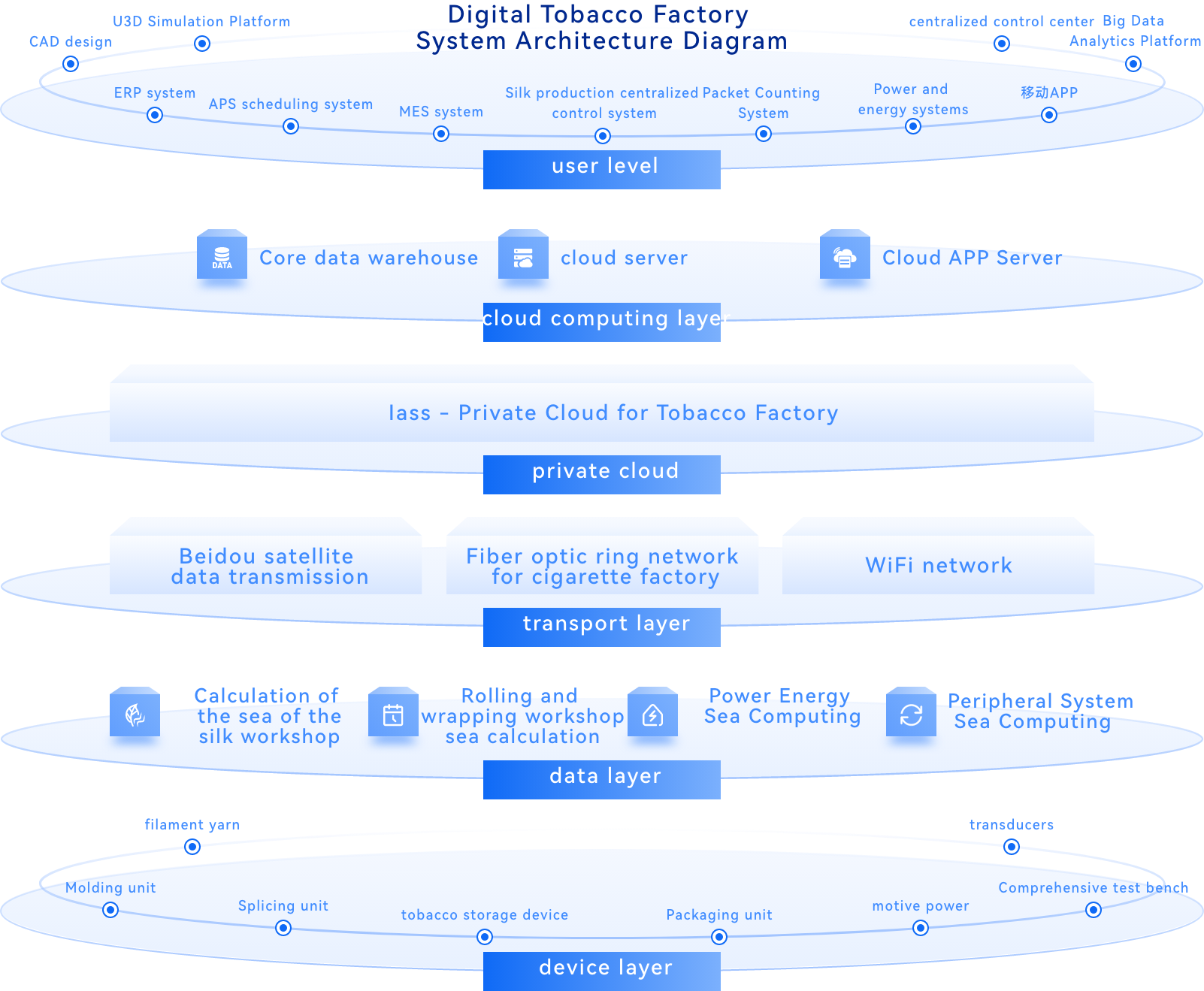

Promoting the realization of digital factory management model for tobacco

Smart Tobacco Factory refers to the application of science and technology and innovation in tobacco manufacturing, taking data as the key production factor, relying on digital technology to promote the enhancement of the level of intelligence in all aspects of tobacco manufacturing, in order to improve the production efficiency and quality stability, reduce costs and improve the level of management as the goal to accelerate the integration of the "Internet +" and the development of traditional industries.

The use of digital technology can realize the analysis and application of production data, real-time monitoring and analysis of production data, including production efficiency, equipment failure rate, product quality and other aspects, so as to optimize the production process.

Through the production planning and process control system, it realizes the automation and intelligent management of the production process, including production task allocation, material distribution, equipment scheduling and automation control, real-time inspection of product quality, etc., so as to reduce labor, material and production waste.

Comprehensive, accurate, real-time collection and acquisition of equipment information, providing production monitoring and management, equipment management, quality management, data management and other functions, standardizing the production management process, and effectively improving production and management efficiency.

Combining the traditional process quality control theory and big data analysis method to build intelligent analysis system, to realize the automation and intelligent management of quality inspection, including automatic acquisition, intelligent identification, real-time feedback and dynamic control, to ensure the stable and controllable quality of key process in the workshop, and to achieve the purpose of improving product quality.