Chinese medicine tablets are in the middle of the traditional Chinese medicine industry, the industry presents "small and complete", "small and scattered" characteristics of the product varieties, different concoctions, processing modular unit operation, production automation and low level of intelligence, there are generally Low production efficiency, high labor costs, difficult to judge the end point, chaotic production management and other pain points.

Chinese medicine tablets are in the middle of the traditional Chinese medicine industry, the industry presents "small and complete", "small and scattered" characteristics of the product varieties, different concoctions, processing modular unit operation, production automation and low level of intelligence, there are generally Low production efficiency, high labor costs, difficult to judge the end point, chaotic production management and other pain points.

Lampo Technology redefines traditional Chinese medicine production mode with AI technology

Redefining Traditional Chinese Medicine Production Model

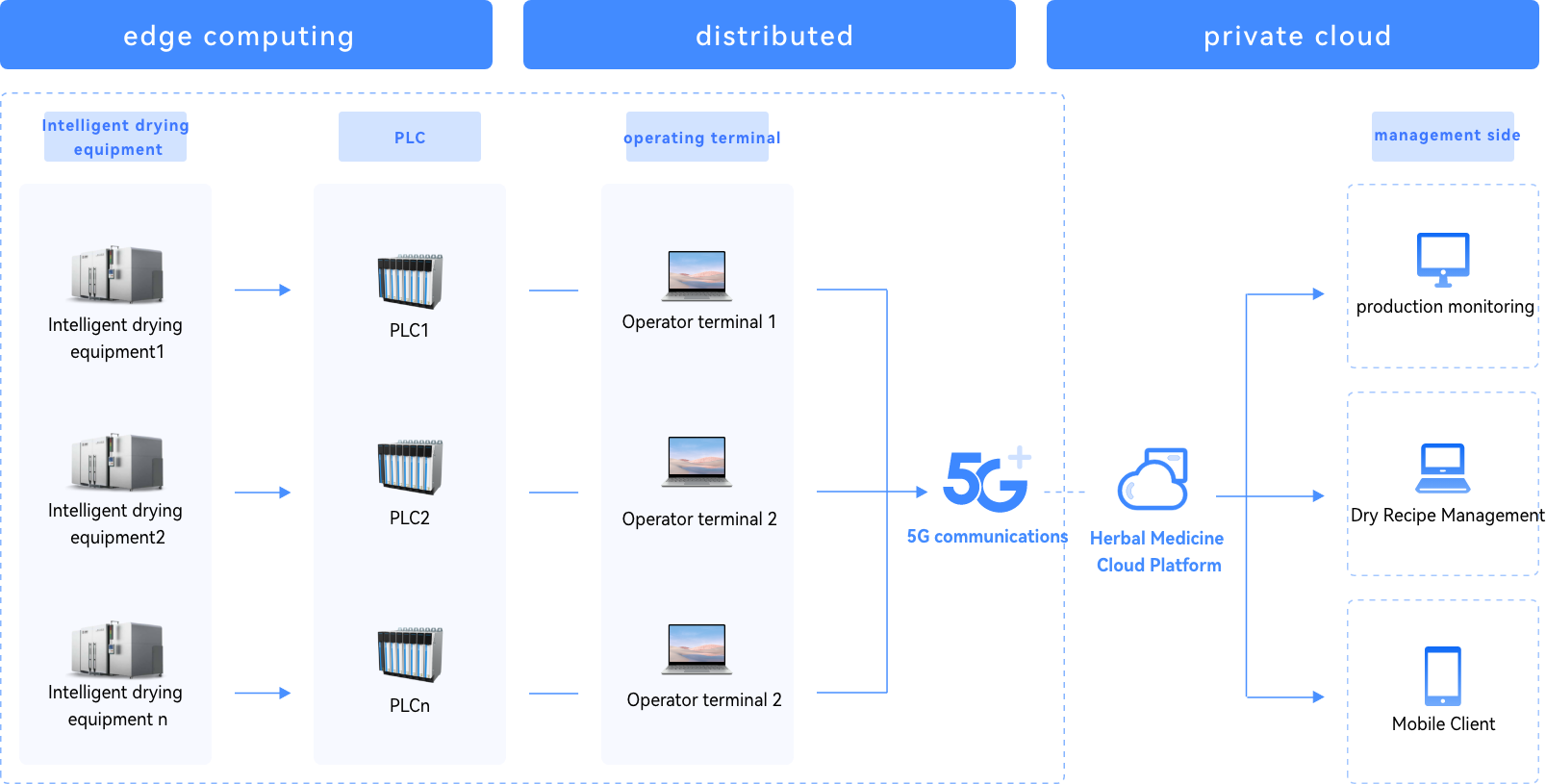

Using computer control, intelligent sensing, AI artificial intelligence, big data, Internet of Things and Internet technology, centering on drying equipment, it is an intelligent Chinese medicine drying workshop management mode that carries out whole-process control and management of Chinese medicine drying process flow, quality control, process formula, equipment and personnel.

Precise control of moisture content and moisture uniformity can significantly reduce the loss of herbs, improve drying quality, reduce labor and energy costs, realize quality and increase production efficiency, and enhance the economic benefits of enterprises.

The quality and quality of Chinese medicine tablets have a great relationship with its drying uniformity, moisture content and temperature control.AI intelligent moisture content control system can realize the fine control of the whole process of drying, stabilize the moisture content and uniformity of the discharged material, and improve the quality of herbs.

The use of automatic up and down material and the entire drying process intelligent, minimize the involvement of manpower, improve the efficiency of the equipment, reduce labor costs, energy costs.

Using intelligent information technology to build a digital production management system, through the collection and analysis of production data, adjustment and optimization of production plans, processes, labor, equipment and energy management, etc., to achieve refined production management