Whether it's ChatGPT, which came out of nowhere earlier, or Sora, which recently burst into flames out of the ring, it's announcing that the development of AI has entered an accelerated stage.

At present, the combination of AI with new drug development, medical services and other fields has become familiar.

As a practitioner of traditional Chinese medicine tablets, we can't help but ask: "AI + drying equipment" can bring what kind of possibilities to the production of tablets?

Drying has always been the most important part of the production process of traditional Chinese medicine tablets, but it has long faced the problems of high energy consumption, high time consumption and high loss.

For the characteristics of multi-variety and large quantity of tablets, based on the traditional open oven and belt dryer, it is difficult for the production staff to control the uniformity and precision of moisture. Once the tablets are dried incompletely or excessively, it will lead to repeated processing, loss of moisture in the herbs, as well as a greater economic loss caused by the decline in the quality of the color, texture and so on.

However, for Lanpu AI, the control of drying tablets is very simple.

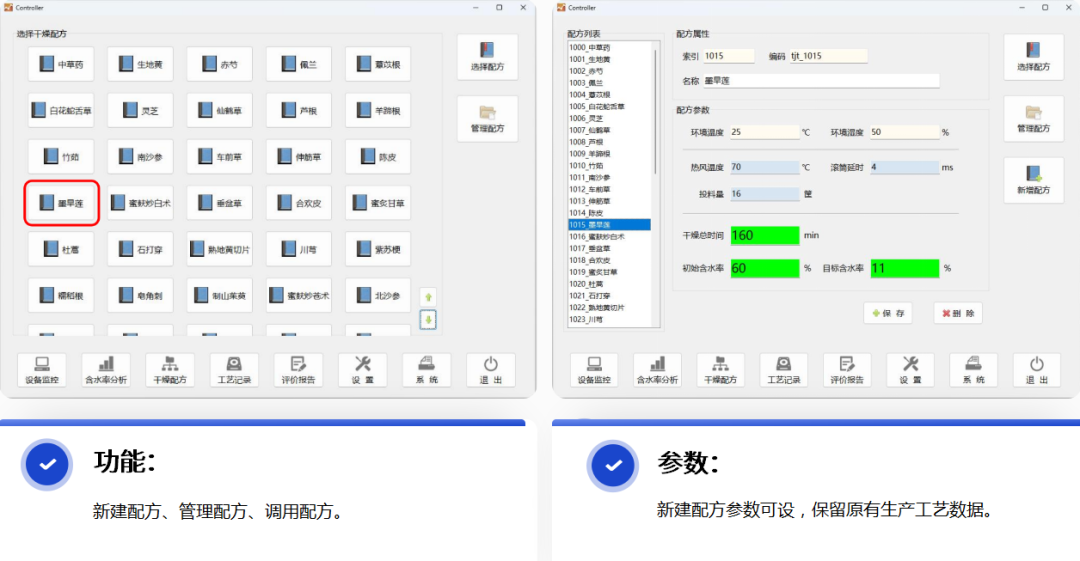

The first is the production formula management.

AI can absorb the decades of experience of "masters" and precisely adjust the parameters in the production process for different tablets with one click, reducing the subjective intervention of personnel and ensuring the stable production of each batch of products, which makes it easy for novice producers to manage and call the formula.

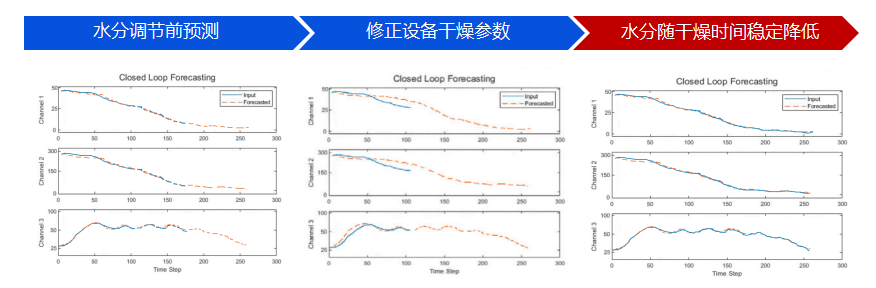

Second is the water content control.

Whether it is traditional equipment such as open oven, belt dryer, or senior "masters" in the industry, they can't always detect the change of water content in the production process of tablets, but Lampu AI intelligent water content control system can. By monitoring the change of water content and establishing the water content model, Lampu AI can dynamically control the drying parameters, realize the fine control of water content, and stabilize the water content and uniformity of the material.

The last is moisture content optimization.

AI also thinks like a human being, analyzes the deviation between the actual moisture and the target value, and finally finds an optimal drying path, so that the moisture content control precision is getting higher and higher.

Industrial change should be actively embraced and accepted. In the wave of AI development, many enterprises are also thinking about what is the focus of the AI era, perhaps "algorithm", perhaps "arithmetic power", but as far as industrial artificial intelligence is concerned, "landing" is eternal. But in terms of industrial AI, "landing" is the eternal theme.

In order to truly perceive and solve the pain points, Lampo Technology insists on change and innovation, leads the practice, plows into the traditional Chinese medicine industry for 6 years, and adopts the idea of "AI + drying equipment" with the ultimate goal of "improving quality and increasing efficiency" to create this intelligent drying equipment for traditional Chinese medicine tablets. drying equipment.

With AI as an assistant, producers can be transformed into experienced "masters", so that enterprises through the water content control to improve the production rate, to achieve the increase in production of medicinal herbs, to achieve a win-win situation in terms of production efficiency and economic benefits.

Return list

Return list