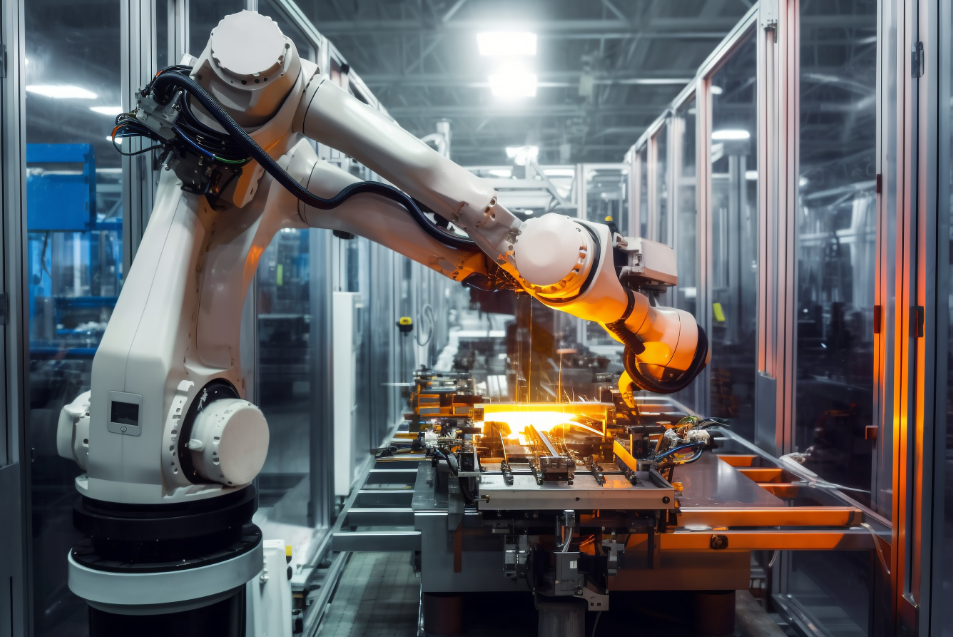

Integrate traditional manufacturing processes, equipment and facilities with digital technologies such as the Internet, Internet of Things, big data, artificial intelligence, etc., to build a highly digitalized and intelligent manufacturing system.

The most important feature of the digital factory is that product design and production can be carried out virtually in the digital space, so that not only the feasibility of product design simulation verification, but also for new products for manufacturability and manufacturing costs in advance of the estimated analysis.

Simulation optimization is the core of the value of the digital factory, according to the established digital model and simulation results given by the simulation system and a variety of predictive data, to analyze a variety of problems that may arise in the digital factory and potential optimization solutions, and then optimize the product design and production process.

In the full life cycle of a product, there exists a list of various data files (BOM) for different departments and purposes. The single data source idea is to form a logical single data source by carefully organizing different data and establishing strict constraints, so as to effectively solve the problem of data redundancy and data inconsistency between different departments.